Useful Tips and Tricks for Users Manage Production

Orders effortlessly

Orders

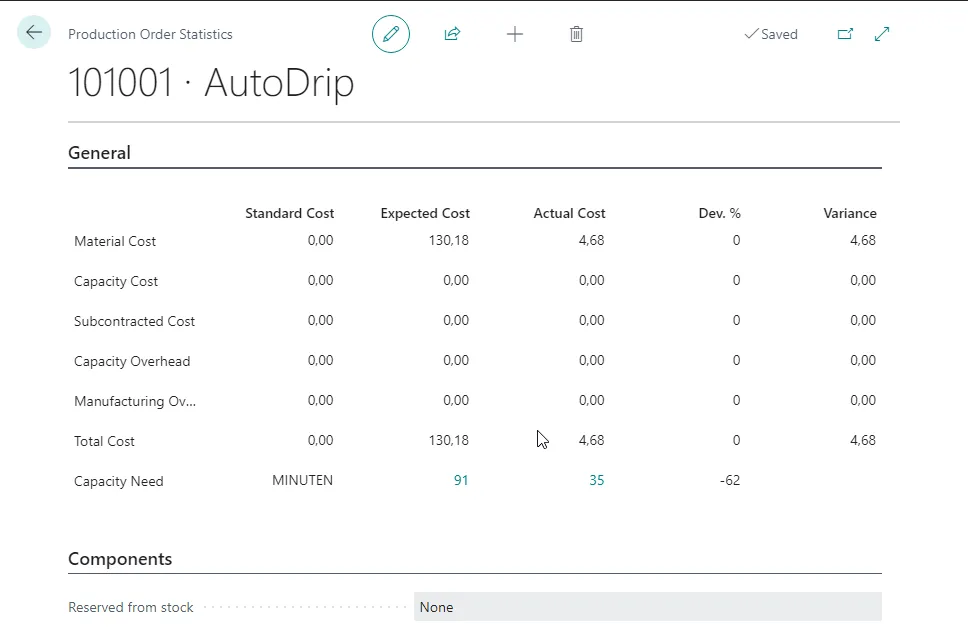

Manufacturing in Business Central enables you to control your production processes efficiently and transparently and supports you in planning, executing and monitoring production 🏭, material management, quality control and cost analysis. By integrating with other modules, Business Central ensures seamless collaboration and provides a holistic view of the entire value chain.

Manufacturing in Dynamics 365 Business Central: important Functions and Features

You can plan material requirements directly from a sales or production order or use conventional production and material requirements planning methods. You can compare the estimated demand with the actual values and create your demand forecasts to improve collaboration and planning.

Dynamics 365 Business Central offers functions for both single and batch production. You have the option to switch flexibly between the two production methods.

You can create specific orders and individually control the manufacturing process for each order using the single manufacturing functions. You can also use the batch manufacturing functions to carry out recurring production orders for a specific number of units.

These functions enable seamless integration between warehouse management and manufacturing. In Business Central, you can create stock-related production orders where the system automatically determines the material requirements from stock levels. Automatic orders can be generated for missing materials or manual requisitions can be created to ensure material flow. This function ensures that the existing stock is used efficiently and reduces bottlenecks or excess stock.

You also have the option of creating MTO production orders based on the individual requirements and characteristics of your customers’ orders.

From the production BOMs in Business Central, you can see which individual parts you need to produce a specific item - a distinction is made between raw materials and semi-finished goods. You also have the option of using multi-level production BOMs. These help you to produce complex products that consist of several sub-components.

The subcontracting functions in Business Central also allow you to clearly display orders that you outsource to subcontractors (vendors).

With the help of various planning options, Business Central enables you to quickly realize special orders and “last-minute” changes in order to adapt to the dynamic requirements of your customers.

Your Benefits 💪

-

Efficient Manufacturing Processes

The manufacturing module in Business Central helps you to optimize your production processes sustainably so that time and costs can be reduced.

-

Optimized Capacity Utilization through an all-round Overview

The permanent overview of all your resources helps you to optimize your technical and personnel utilization.

-

Short Response Times thanks to Flexibility

If your customers’ requirements change at short notice, you are in a position to respond promptly.

-

Transparency and Traceability of all Processes

Clear digital production orders and BOMs ensure that the manufacturing processes are fully traceable and transparent for your employees.

-

High Planning Reliability enables 100% Adherence to Delivery Dates

You have high planning reliability and can meet scheduled delivery dates in almost 100% of cases. This allows you to achieve even better customer satisfaction.

More information

on the topic Manufacturing

on the

Fully integrated

Fully integrated