Useful Tips and Tricks for Users Manage Warehouse and

Logistics with Ease

Logistics

The warehouse and logistics functions of Dynamics 365 Business Central support you in optimizing your warehouse and shipping processes 📦, inventory tracking and planning, and collaboration with suppliers. Thanks to integration with other modules such as sales and finance, seamless collaboration is possible, improving the efficiency of the entire company.

Warehouse and Logistics in Dynamics 365 Business Central: important Functions and Features

The order processing is seamlessly integrated into the production and warehouse processes in order to optimize warehouse allocation and utilization as well as to efficiently manage item procurement and process several orders at the same time.

The ADCS (Automated Data Capture System) allows you to capture data from various sources automatically and integrate it seamlessly into the Business Central system. This is beneficial when barcode scanning or RFID technologies are used. In this way, you can improve transparency, accuracy and efficiency when picking goods and carrying out put-away processes. The same applies to counting and item transfers.

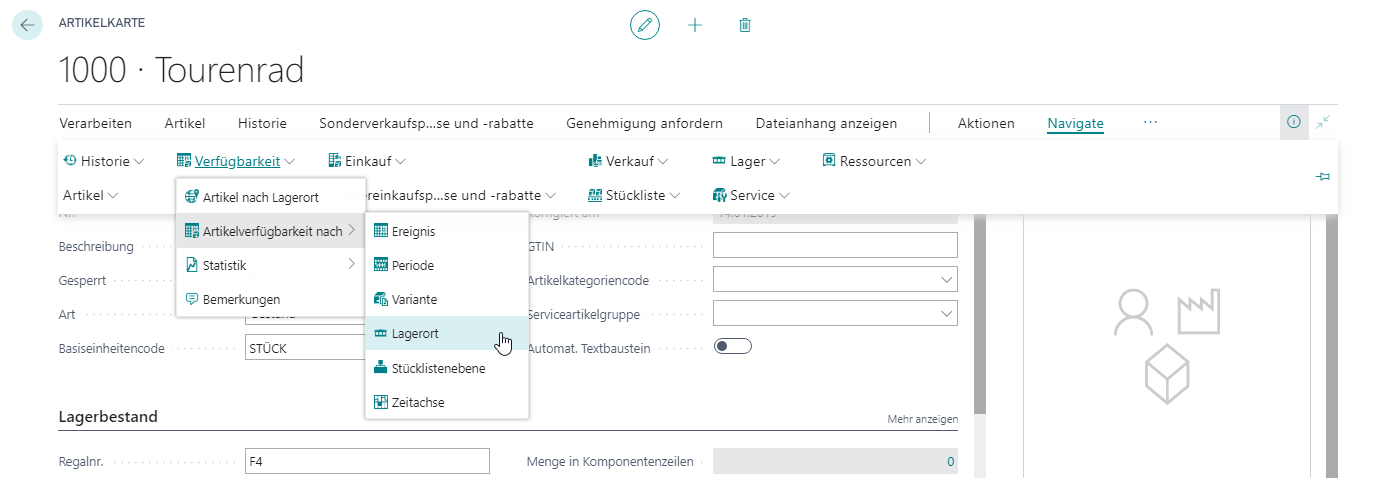

The tracing of batch and serial numbers helps you to quickly identify purchases, edits and sales of an item. You can also use the FEFO (First Expired - First Out) method to prevent stock waste. The availability of items can be checked in real time.

The frequency of item counts can be determined on the basis of stock maintenance data. This helps you to ensure optimal stock levels and guarantee on-time deliveries.

In Business Central, you can efficiently manage shipping processes by planning shipping processes, creating shipping notes and shipping labels and enabling shipment tracking. You can also manage transport orders and optimize cooperation with shipping companies.

Relevant information about your suppliers can be recorded and managed centrally, including contact details, contracts, price lists and delivery conditions. This facilitates collaboration and communication.

Your Benefits 💪

Optimized Warehouse and Logistics Processes

The improved planning and automation of processes enable faster, more efficient and smoother order processing and reduction of the error rate.

Cost Savings through improved Capacity Utilization and a lower Rejection Rate

By optimizing occupancy and utilization rates in the warehouse, reduced capital commitment can be achieved, resulting in cost savings. Costs can also be decreased by reducing waste.

Real-time Overview and permanent Transparency

There is a precise overview of articles, availability, orders and suppliers at all times. Relevant data can be checked in real time, ensuring transparency and traceability at all times.

On-time Deliveries and efficient Collaboration

With high planning reliability, you ensure that promises to suppliers and your customers are always kept. This improves collaboration and increases the satisfaction of all parties in the supply chain.

More information

on the topic Warehouse & Logistics

on the

Fully integrated

Fully integrated